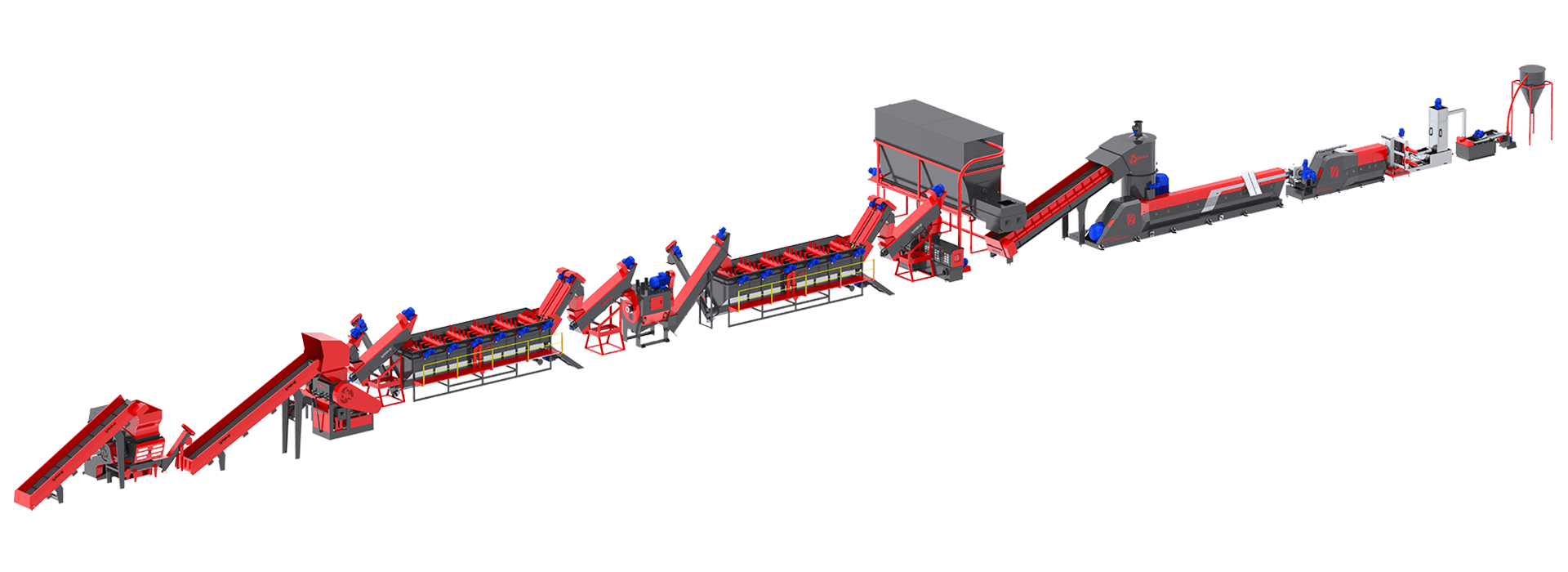

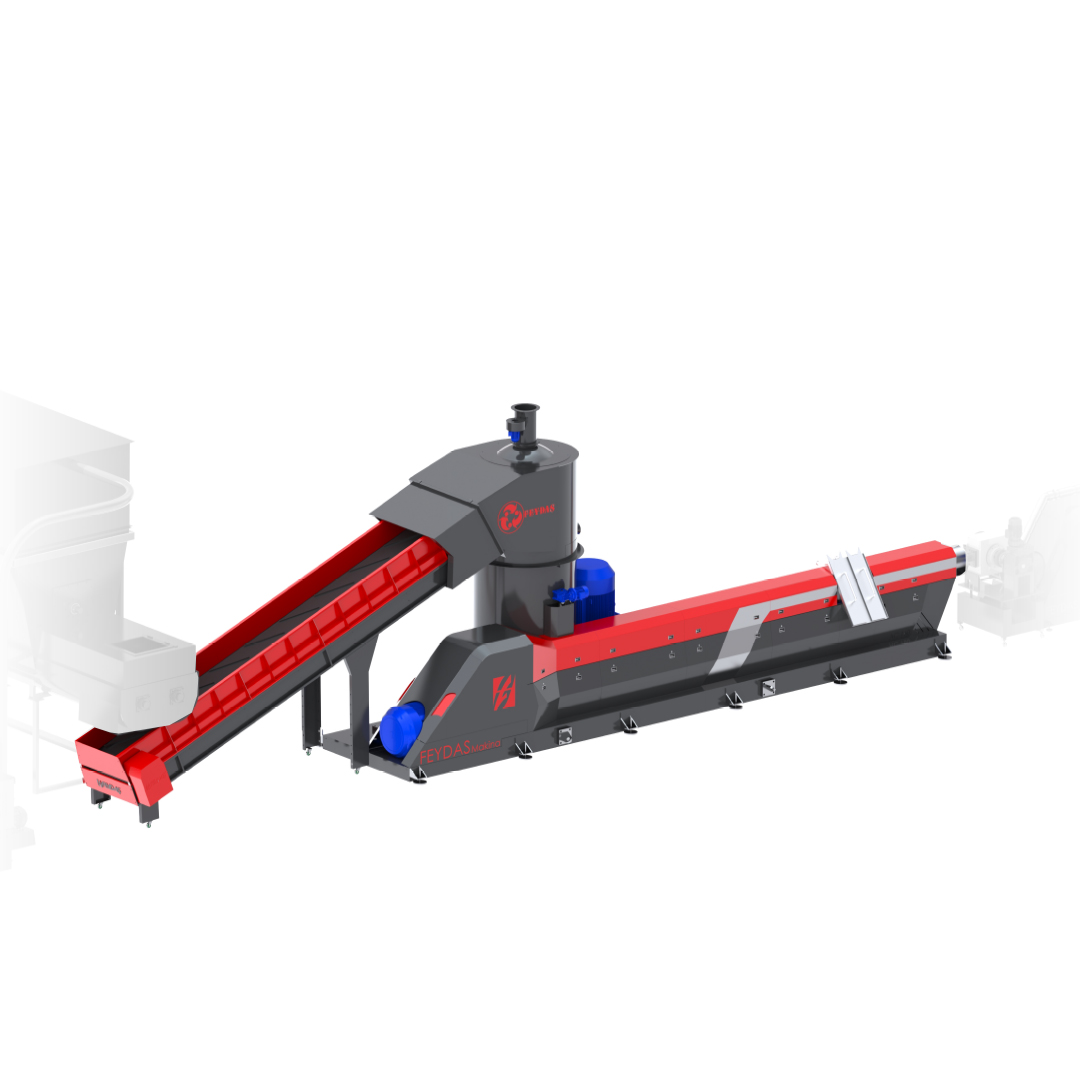

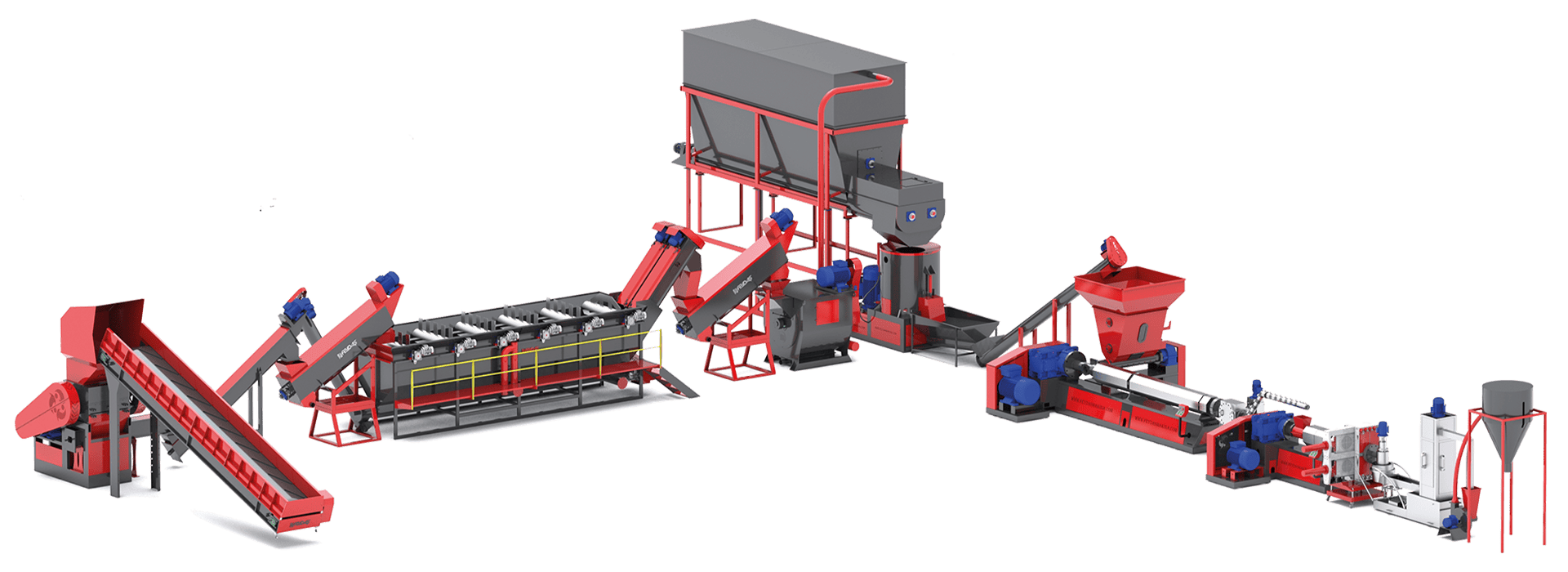

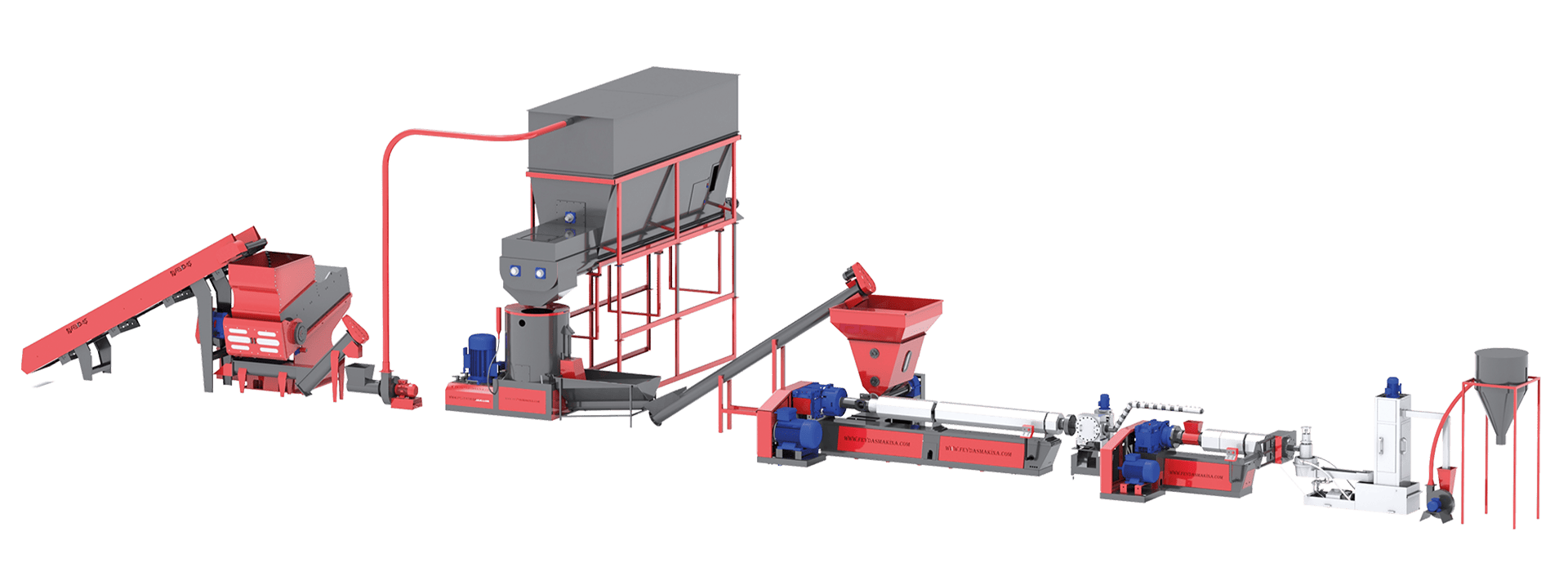

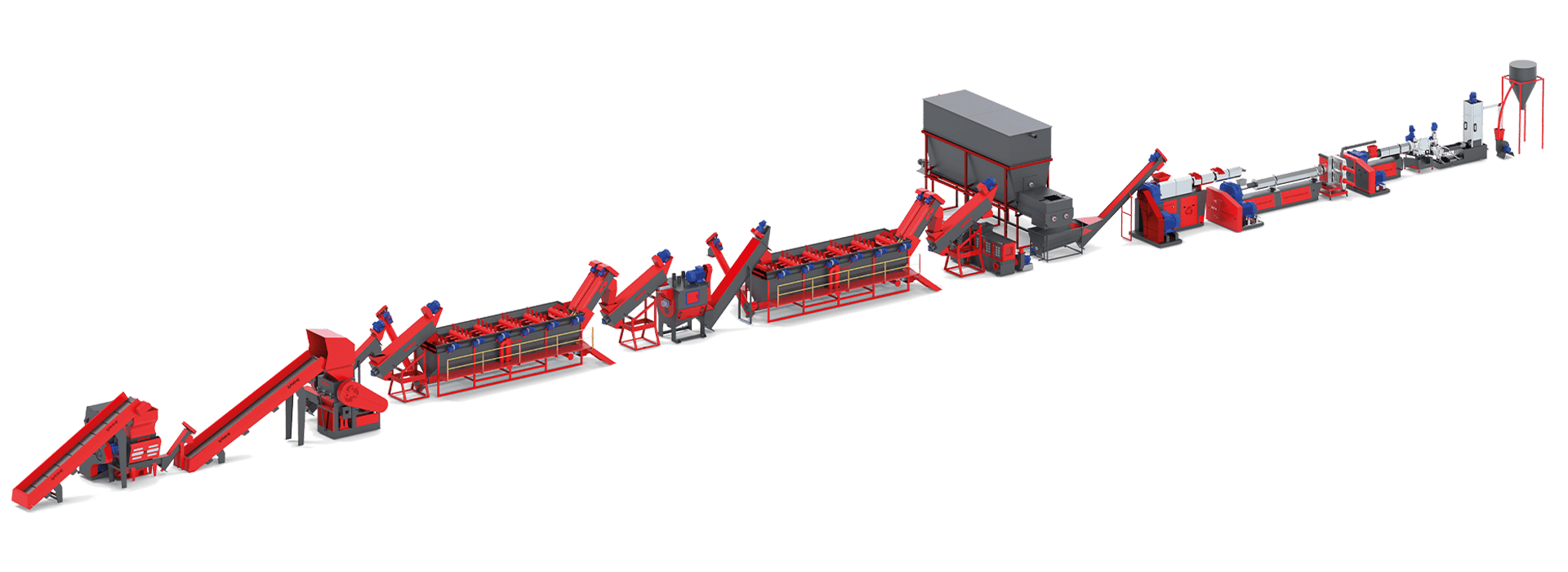

PE PP FILM PLASTIC WASHING AND GRANULE PRODUCTION LINE

HOW IT WORKS

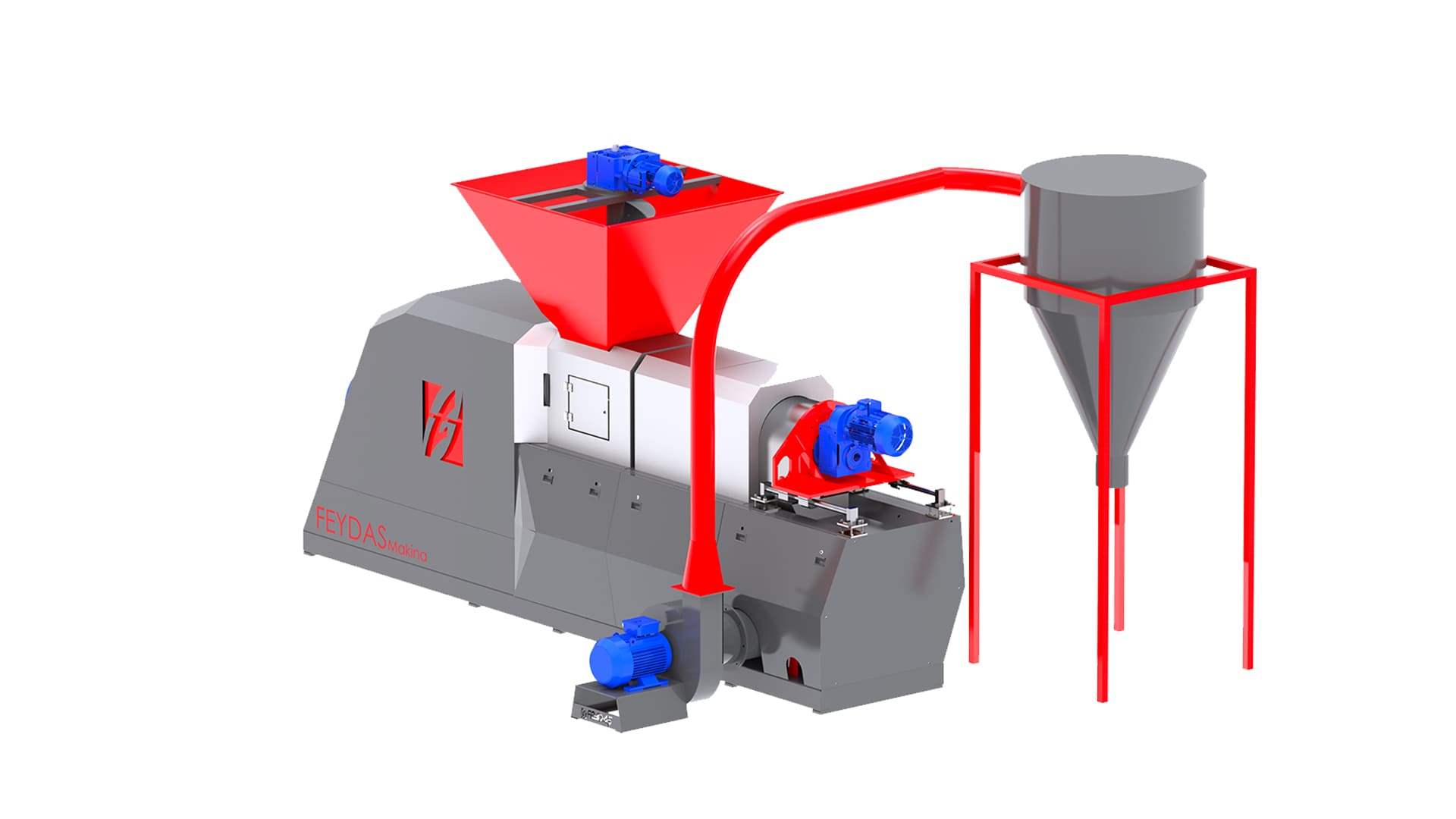

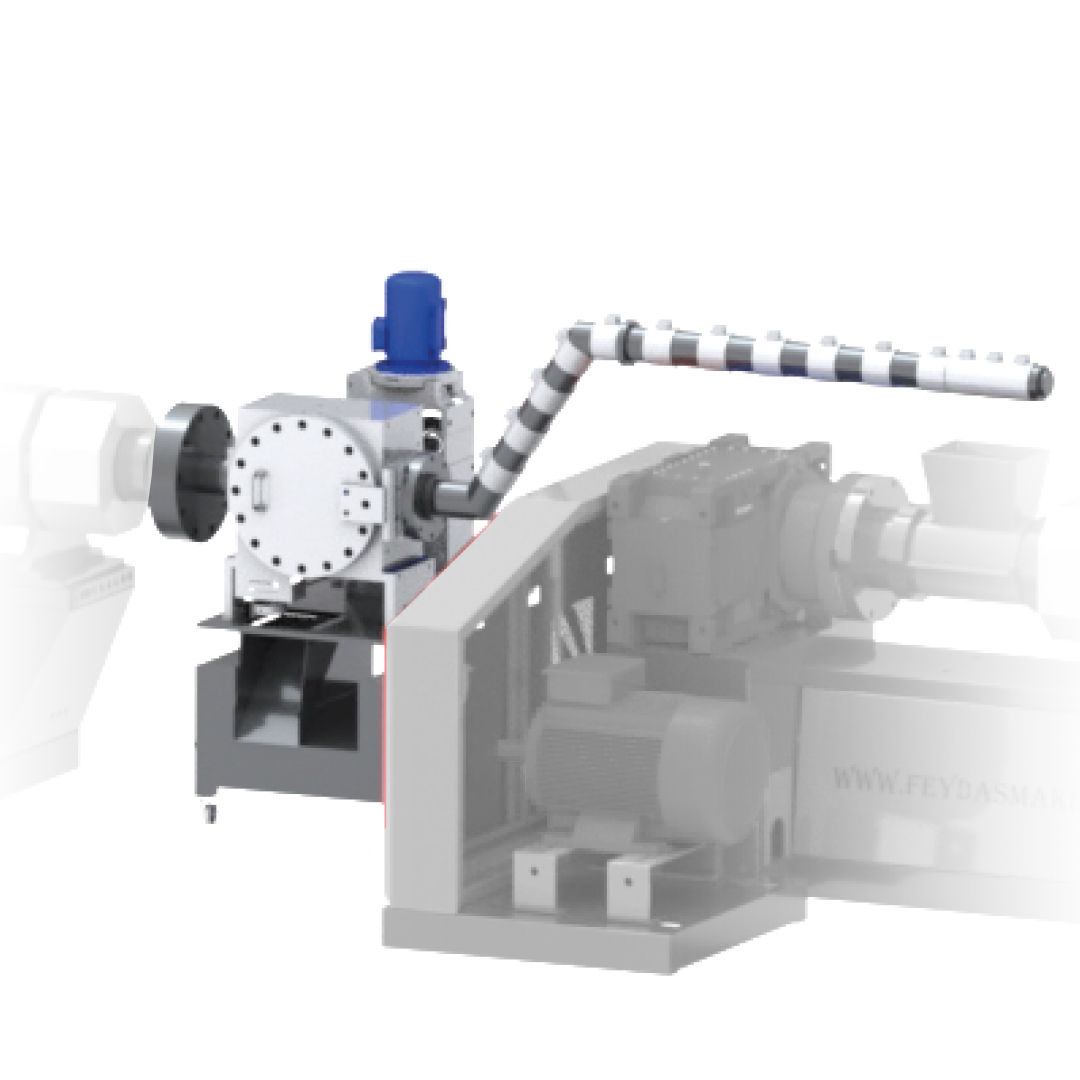

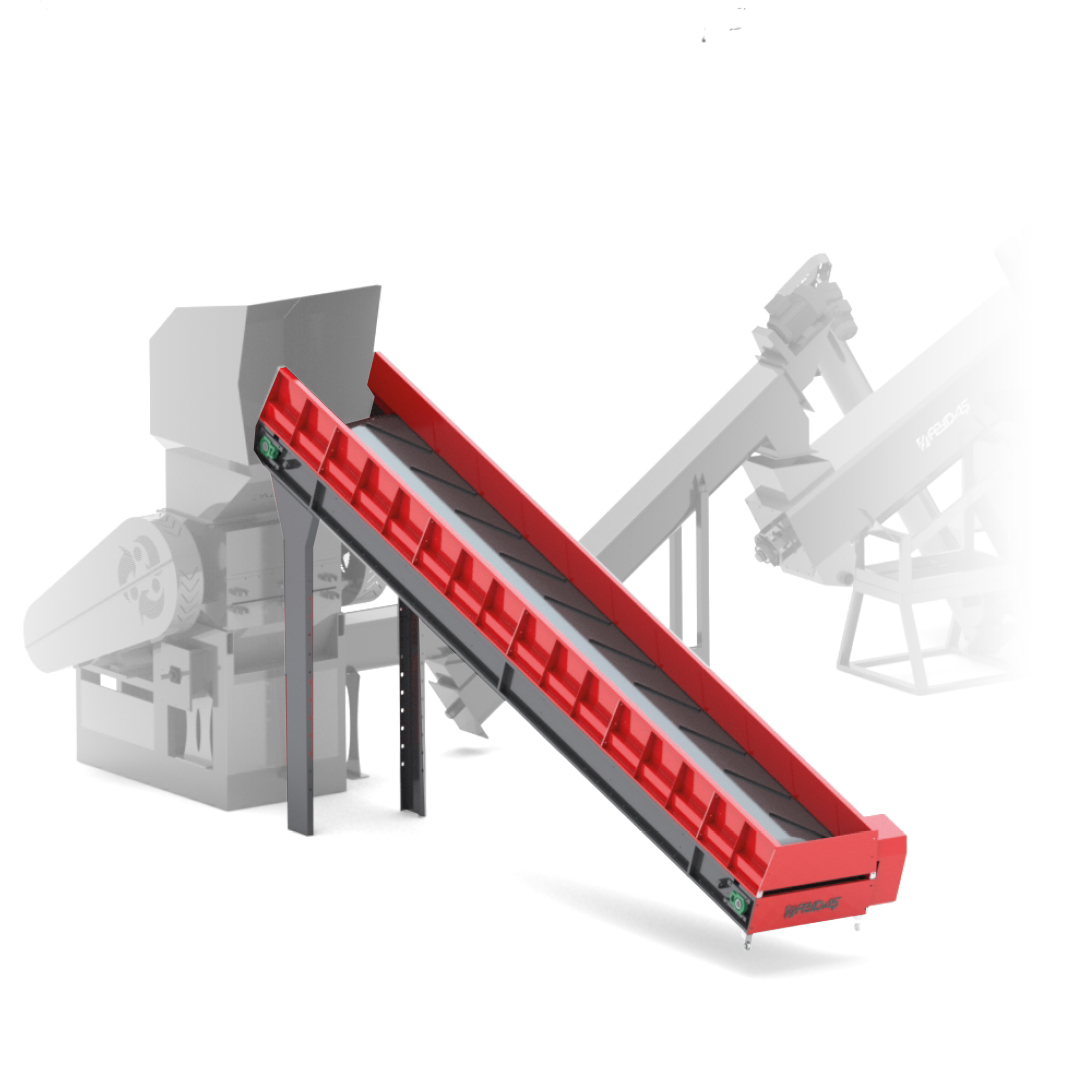

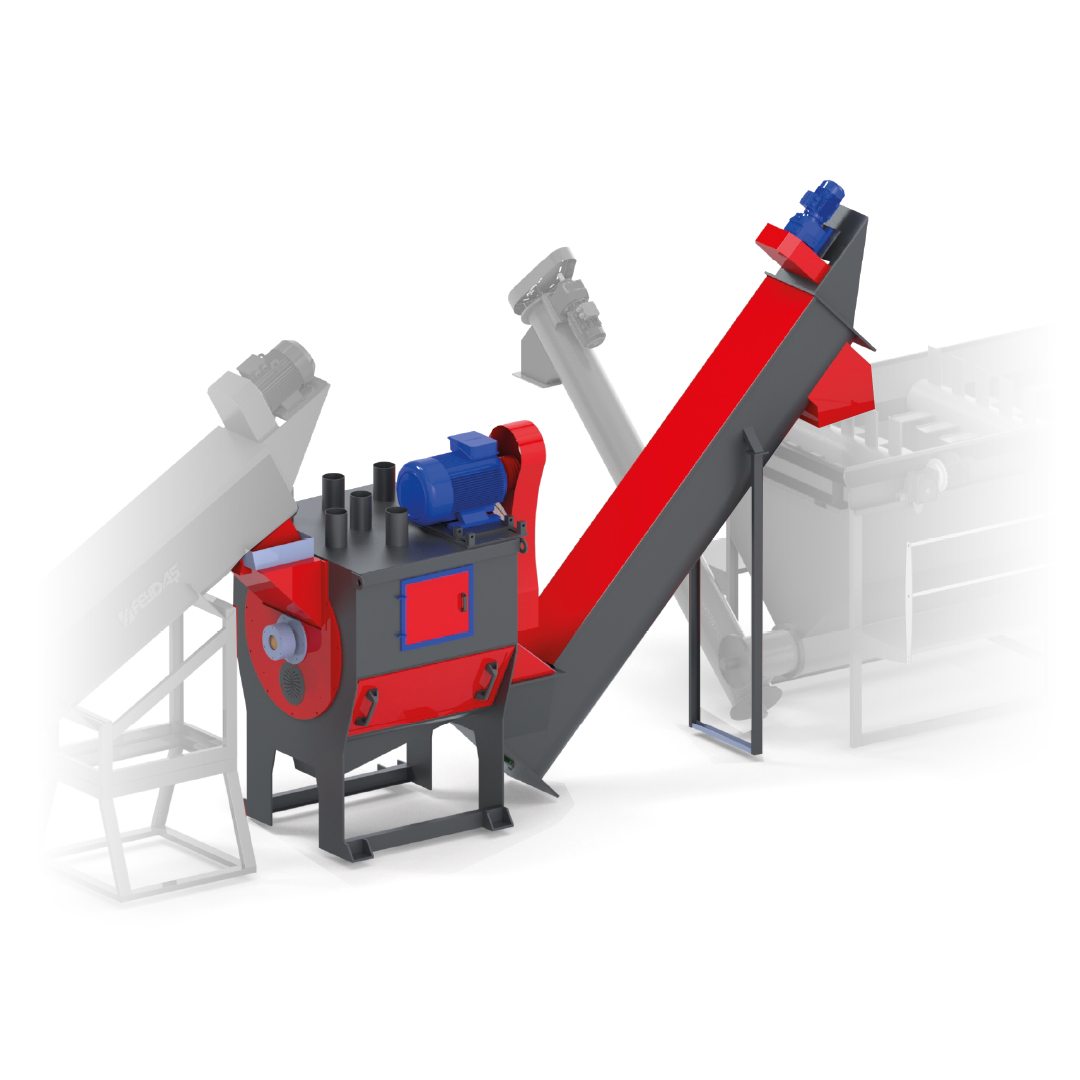

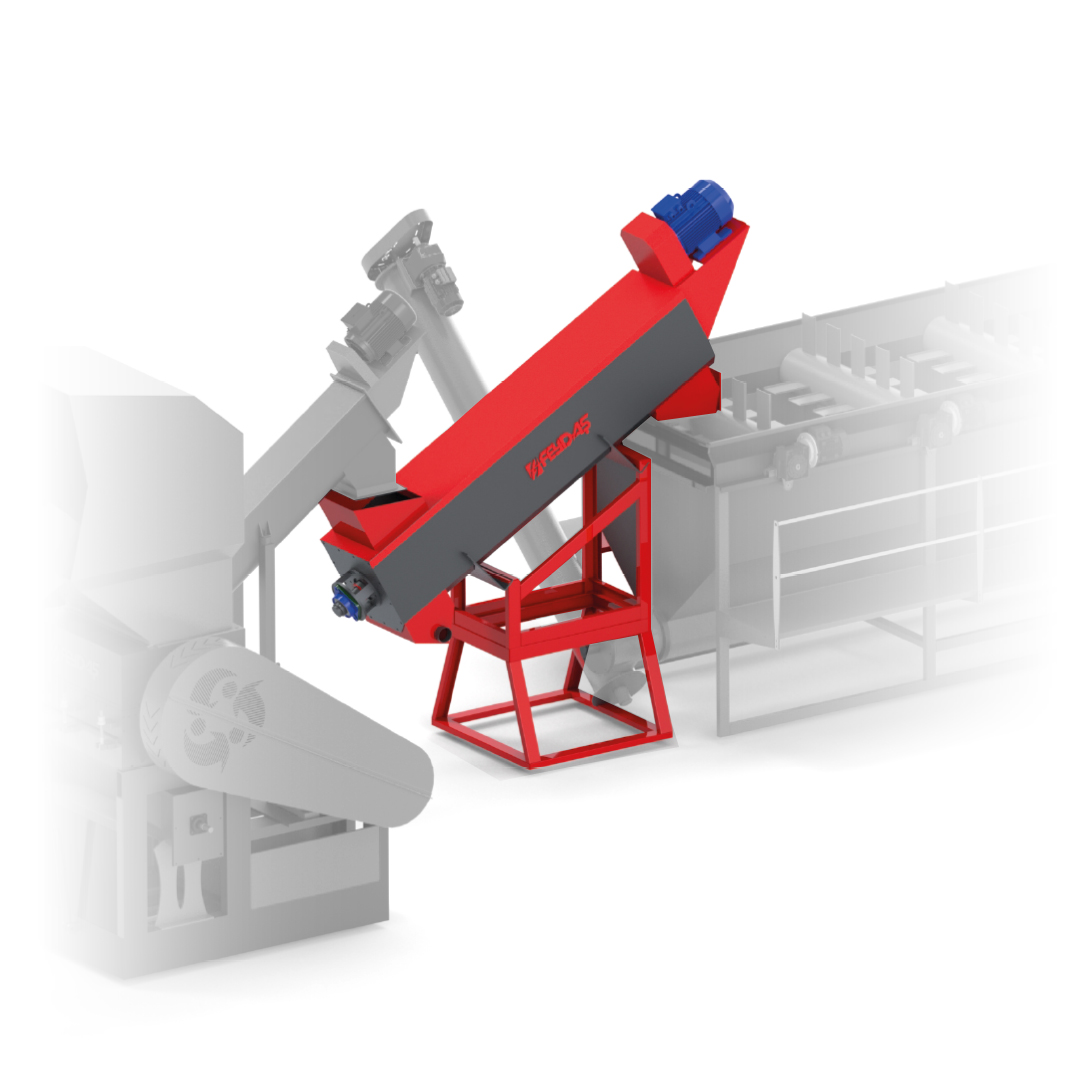

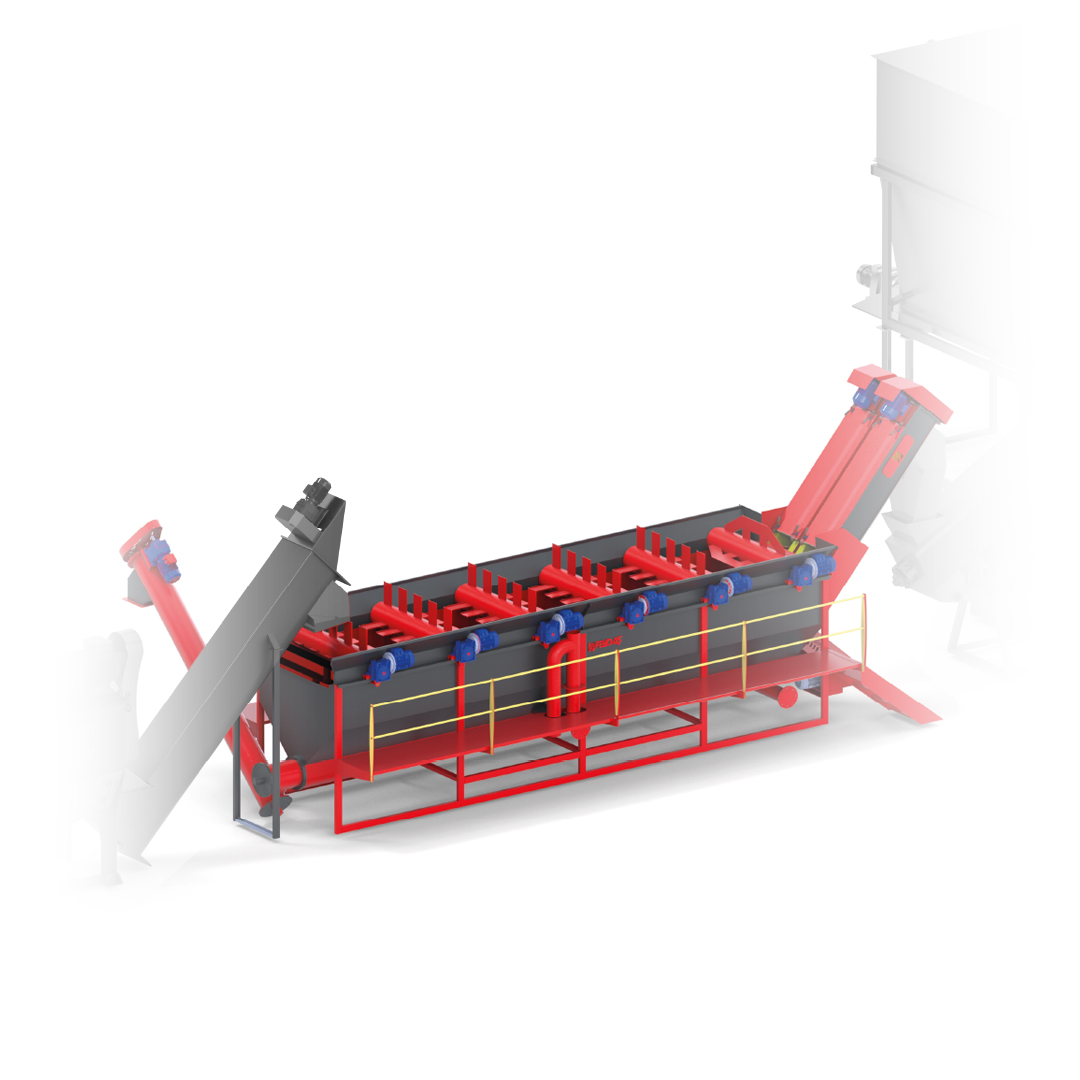

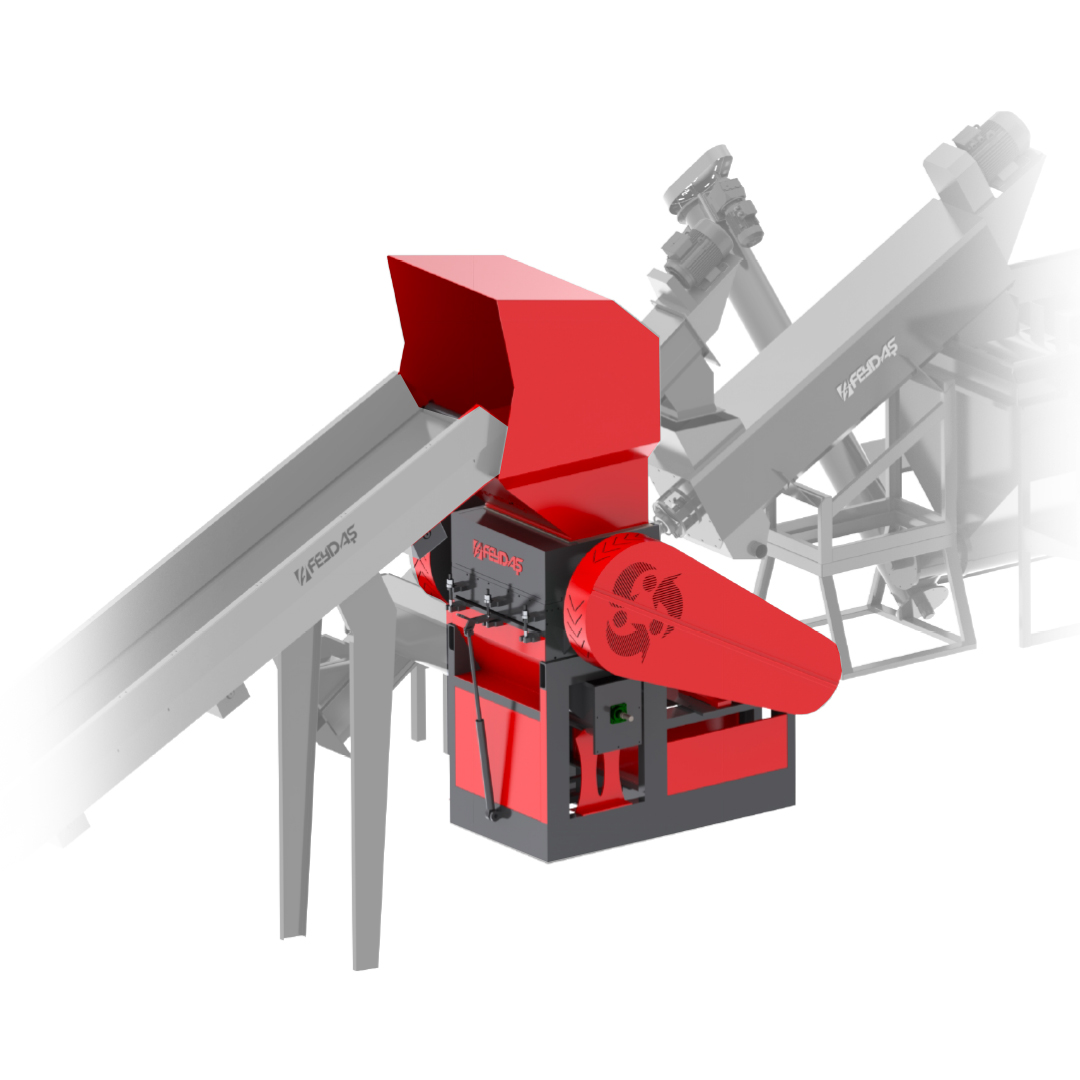

The recycling process of PE (Polyethylene) and PP (Polypropylene) plastics involves cleaning waste plastics and converting them back into raw materials. This process consists of the following main stages: crushing, washing, drying, and granulation. 1. Feeding and Pre-Sorting Plastic waste is fed into the system via a conveyor belt. Large foreign materials and metal parts are removed using magnetic separators to prevent damage to the system. 2. Crushing (Shredding) Plastic materials are broken down into small pieces using powerful shredding machines. This step ensures a more effective washing process in the next stage. 3. Washing and Separation The crushed plastics are placed in water tanks to remove dust, dirt, oil, and other contaminants. Based on density differences, heavy dirt and metals sink, while lighter plastics float to the surface. 4. Centrifugal Drying and Thermal Drying Cleaned plastics are spun at high speeds in centrifugal machines to remove excess water. Then, hot air drying is applied to minimize moisture content. 5. Extrusion and Granulation Dried plastic pieces are fed into extruder machines, where they are melted at high temperatures. The molten plastic is passed through filters to remove any remaining foreign substances. It is then drawn into thin strips, cooled, and cut into small plastic granules using granulation machines. 6. Storage and Reuse The resulting PE or PP granules are bagged and stored for reuse in production processes or for sale. This process ensures that waste plastics are repurposed, contributing to an environmentally friendly production cycle.

Other Product Lines

HARD PLASTIC WASHING AND GRANULE LINE

See Product

CLEAN PLASTIC GRANULE LINE

See Product

PE PP FILM PLASTIC WASHING AND GRANULE PRODUCTION LINE

See Product