After the filter process of the main extruder, co-extruder ensures that removal of 100% of the gas inside the product or similar steam released due to humidity. In addition, after compressing the plastic again and performing a second extruder process, the product is filtered again. In this way, the plastic is ensured to be smoother and more homogeneous.

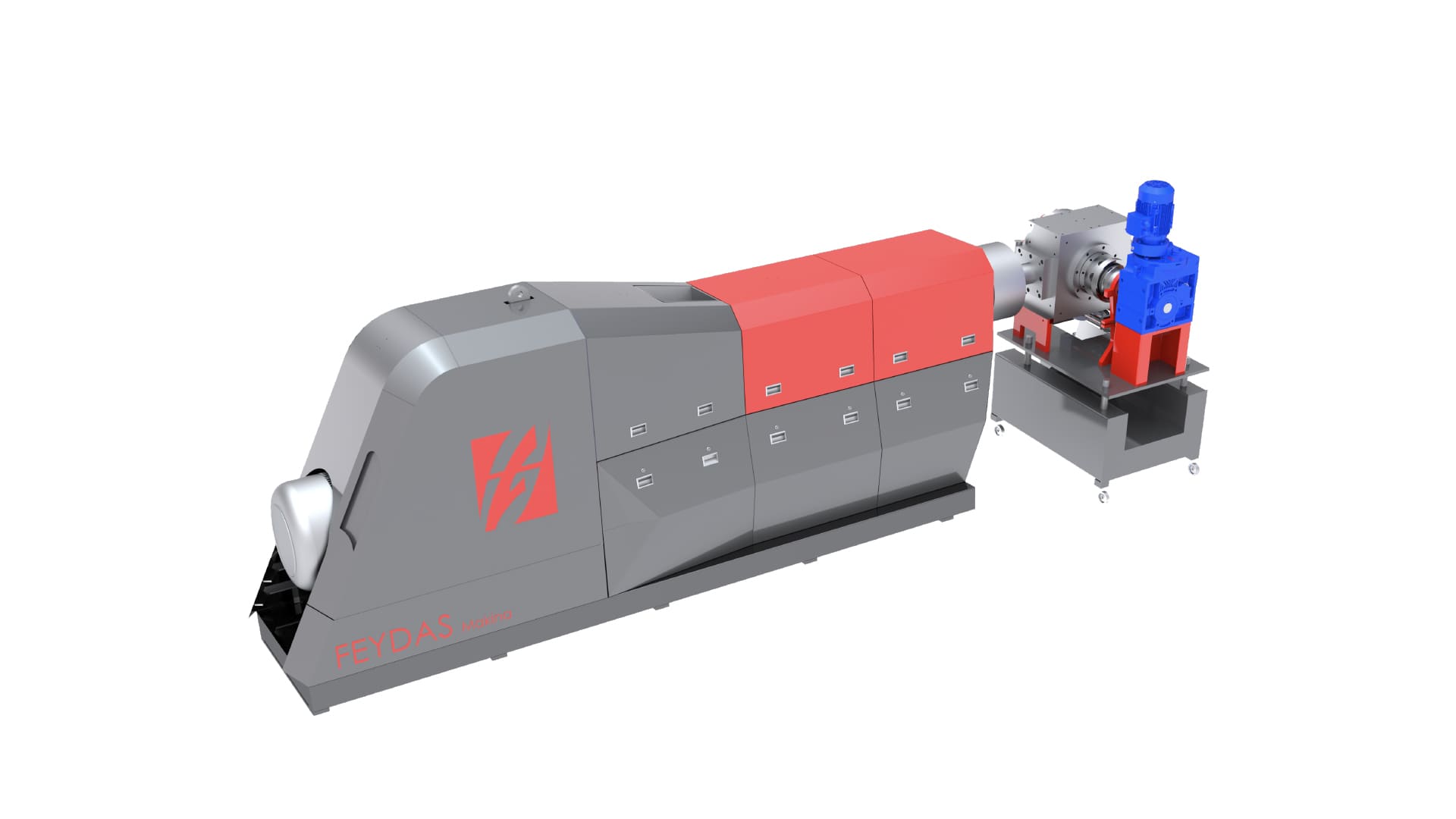

Side Extruder Machine Details

| MODEL | CO-DRAGON 170 | CO-DRAGON 200 | CO-DRAGON 200 GAZ ALMALI-DEGASSING |

|---|---|---|---|

| CO-EXTRUDER SCREW DIAMETER | 170 MM | 200 MM | 200 MM |

| 330 MM SINGLE | 330 MM SINGLE | 330 MM SINGLE | |

| FILTER DIAMETER | 330 MM DOUBLE | 330 MM DOUBLE | 330 MM DOUBLE |

| 400 MM AUTOMATIC | 400 MM AUTOMATIC | 400 MM AUTOMATIC | |

| 600 MM LASER | 600 MM LASER | 600 MM LASER | |

| MACHINE LENGTH | 3500 MM | 4000 MM | 5885 MM |

| RAW MATERIAL INPUT HUMIDITY | %0 | %0 | %0 |

| MOTOR POWER | 55-90 KW | 75-110 KW | 90-160 KW |